Advantage

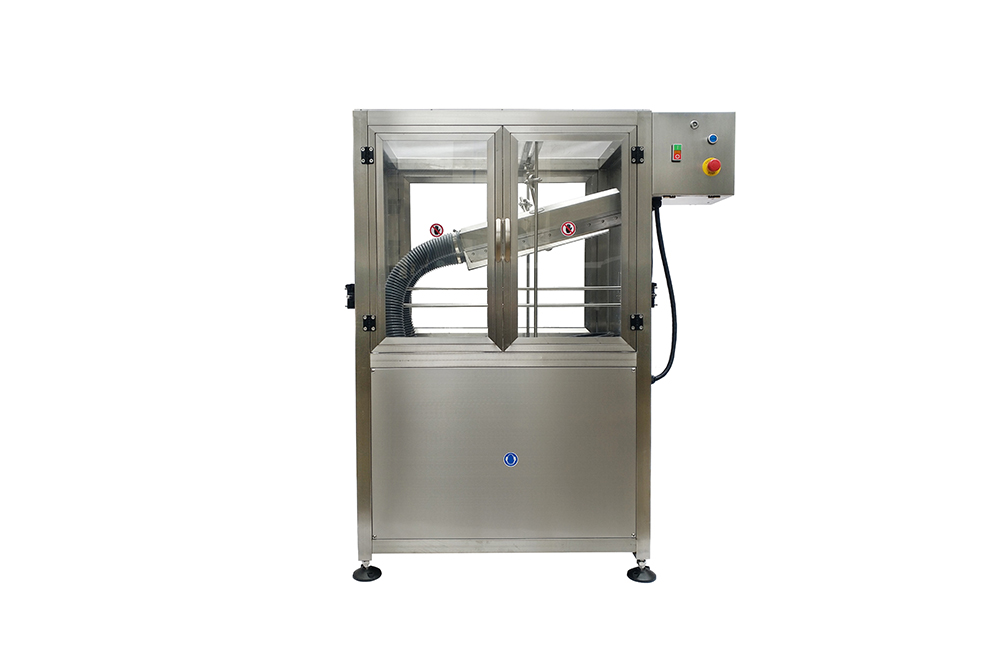

- (1) Two holders for two rolls of sleeves labels.

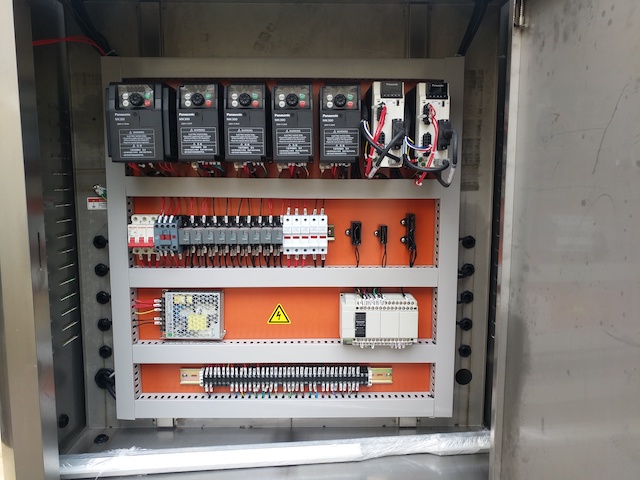

- (2) High speed of servo system, Machine works Stable and reliable.

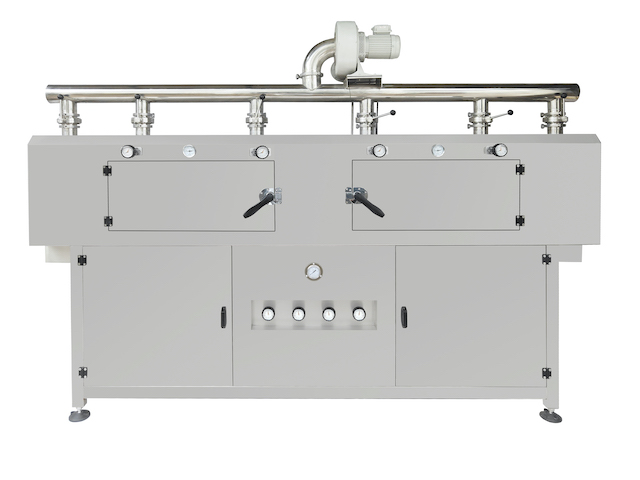

- (3) Elegant appearance, compact structure. Easy operation.

- (4) Simple mandrels holder, easy parts changing process.

- (5) Special cutter design, smoother cutting, quick and easy blades replacement.

- (6) Sleeve inserting only when bottles come, no sleeves wasting.

- (7) Skilled program in PLC makes machines working fluent.

- (8) High eligibility of sleeves inserting.

- (9) The frame is made of 304 stainless steel, no rusting problem.