Gas Fired Steam Boiler

The steam boiler (50-100kgsteam/hour) , used to work together with steam shrink tunnel and shrink sleeve labeling line.

Normally boiler models below match different models of steam tunnels

Email: bishop998@126.com

Tel/Whatsapp: 8613127538116

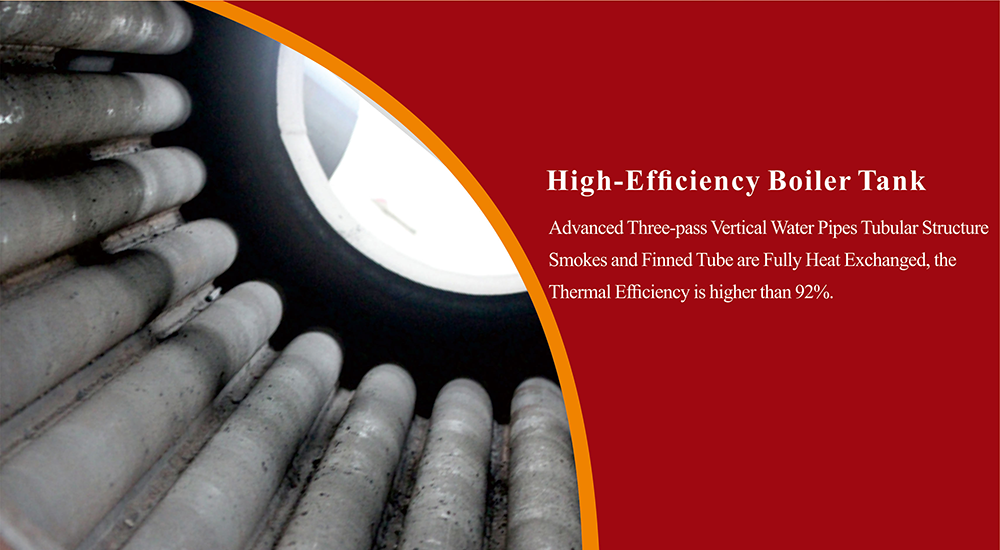

Steam Generator liner uses internationally advanced three-pass vertical water pipe tubular structure, the exhaust gas and finned tube are fully flushed and exchange heat with thermal efficiency of above 92%. Designing by regarding the steam boiler and burner as a whole, and this kind of customized design according to characteristics of boiler is a tradition of our factory, which could make the combustion system of the boiler reach an optimal ratio. It is an organic combination of energy saving with environmental protection technology.

2.Advanced Automatic Control Function

The Steam Generator operating system is automatic controlled, and all the operating state could be seen on the LCD screen. You could observe the working state of the burner on the display screen, boiler water level state, current temperature, feeding pump operating state as well as fault and alarm state etc, making you know the operating condition of the boiler at any time, and use at ease. The most simplified one key control, with one touch to enter the automatic operating state, all safety protection devices start to work without any special personnel to be on duty, making operators more relieved and freer from worry.

3.Safe and scientific structural design

It is equipped with multiple interlock protection devices such as safety valve, pressure controller, water level controlling protector, etc., ensuring absolute safety and reliability. Adopt the rectangular fin tube and tubular furnace structure which can compensate the thermal expansion effectively, prevent thermal stress, make the boiler structure be safe and reliable, and lengthen the service life of the boiler.

4.High-quality and fast steam

The unique design of small water volume and large steam kiln bring fast steam generation within shortest time, and the built-in steam-water separating device guarantees top-quality steam of high dryness.

|

Model |

LSS0.05-0.7 |

LSS0.1-0.7 |

|

|

Rated evaporation(kg/h) |

50 |

100 |

|

|

Rated pressure (Mpa) |

0.7/1.0 |

0.7/1.0 |

|

|

Steam temperature (℃) |

170/185 |

170/185 |

|

|

Fuel |

Diesel (kg/h) |

3.2 |

6.1 |

|

Coal gas (Nm3/h) |

8.9 |

17.0 |

|

|

Nature gas (Nm3/h) |

4.0 |

7.6 |

|

|

Liquefied gas (kg/h) |

3.3 |

5.7 |

|

|

Dimensions |

Length, MM |

800 |

900 |

|

Width, MM |

800 |

900 |

|

|

Height, MM |

1400 |

1800 |

|

|

Steam caliber |

DN15 |

DN25 |

|

|

Drain outlet caliber |

DN15 |

DN25 |

|

|

Water inlet caliber |

DN15 |

DN15 |

|