- Mobile: +86-131-2753-8116

- WhatsApp: +8613127538116

- Skype: zhang7418528

- E-mail: bishop998@126.com

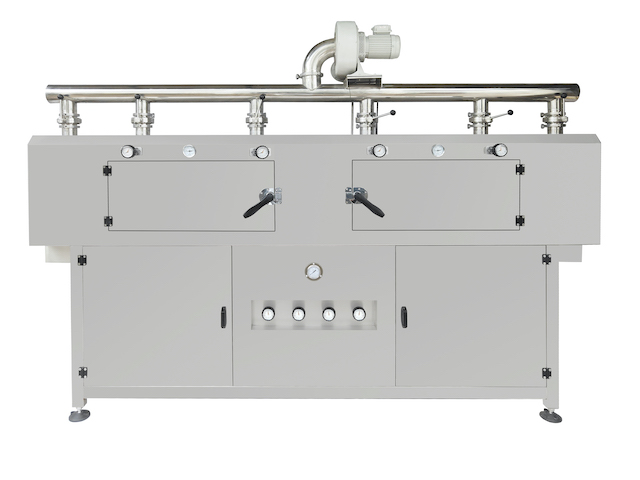

To suit kinds of bottles and different sleeve position, there are some differences with each set machine, such as bottles separating device, sleeve reel in ground or not, brushes/sleeve patting device…

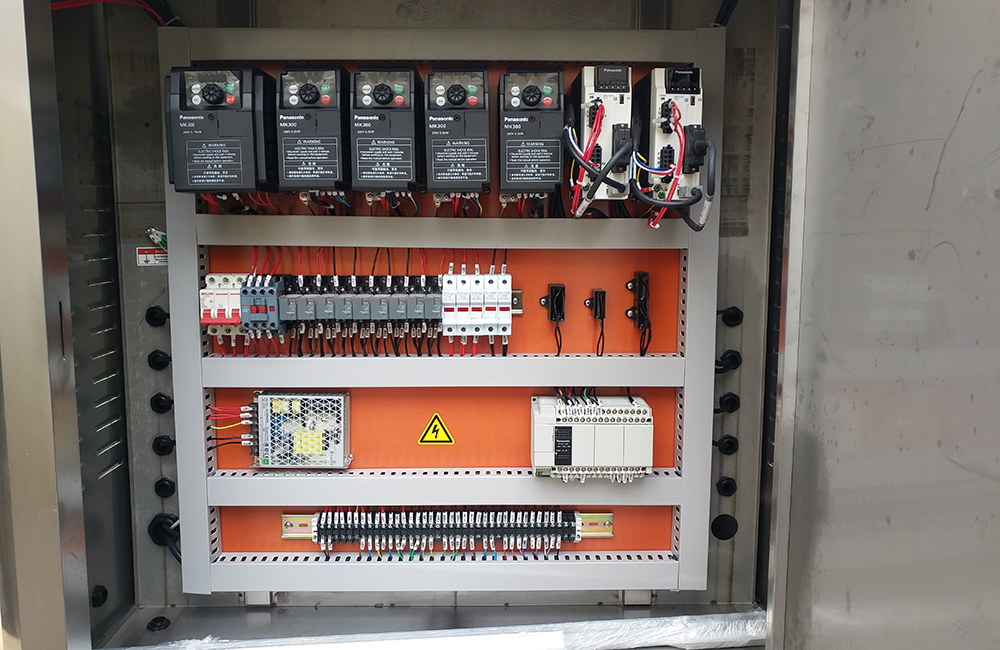

Electrical cables/wires in the cabinet on the back of machine, are assembled by CE standard for EUROPE market.

Advantage

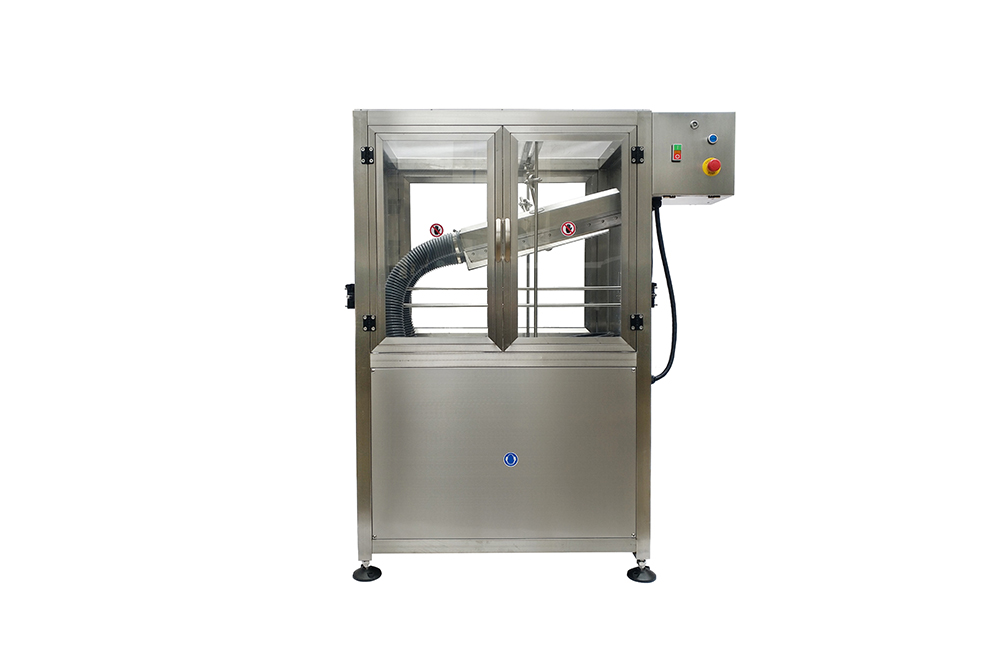

(1) Machine works Stable and reliable.

(2) Servo system drives the machine.

(3) Belt driving cutter, quick and easy blade replacement.

(4) Easy to change mandrels and bottles separating worms to suit different bottles.

(5) No bottles, no sleeve inserting.

(6) Mature program makes machines working stably.

(7) Innovative machine structure design ensures excellent durability and unmatched structural quality.

(8) Speed of Sleeve inserting to bottles is adjustable, work for more kinds of bottles.

(9) The frame is made of 304 stainless steel, no rusting problem.

|

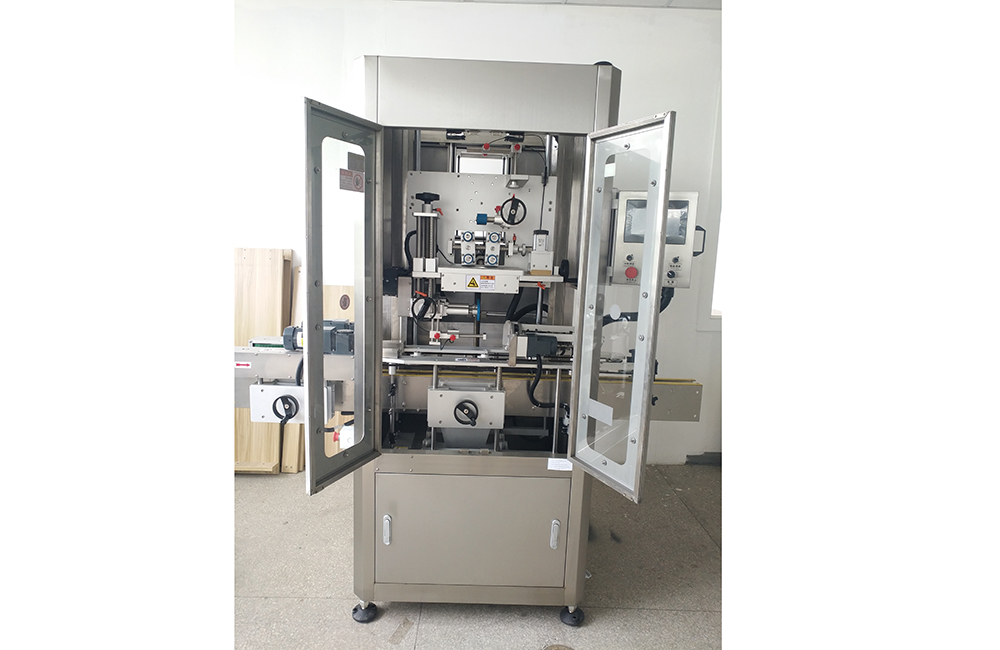

Machine |

Machine model |

HF-250M |

|

Capacity |

250bpm (sleeve height 8~10cm) |

|

|

Size L*W*H |

2000*850*2000mm |

|

|

weight |

650Kgs |

|

|

Powder supply |

AC 220V Singe phase or 220V 3phases |

|

|

Eligibility percent |

≥99.5% |

|

|

Total powder |

2.5KW |

|

|

Shrinkable labels |

Materials |

PVC、PET、OPS |

|

Thickness |

0.035~0.05mm (3.5~5 micro meter) |

|

|

Labels height |

40~300mm |

|

|

Flat width |

Max210mm |

|

|

Core Dia. Of Labels roll |

76mm or 127mm |

|

|

Bottles to pack |

Height |

Max330mm |

|

Diameter |

Ø22 Ø125mm |

|

|

Material |

Glass、Metal 、Plastic |

|

|

Shapes |

Round, square, flat , curved cup-shaped bottles |