- Mobile: +86-131-2753-8116

- WhatsApp: +8613127538116

- Skype: zhang7418528

- E-mail: bishop998@126.com

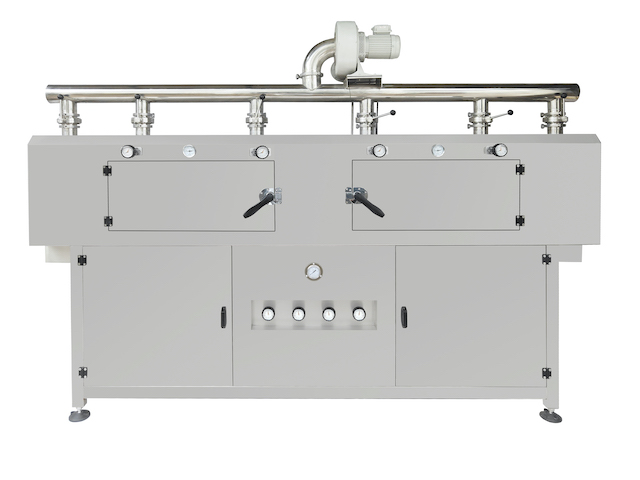

Steam Heat Tunnel

(1) Superb shrink finish with filled or cold bottles

(2) Windows are installed inside of tunnel’s body with water leaking holes, no water getting out.

(5) 6 Steam spray tubes are adjustable for complex shapes of bottles.

(6) Exhausting blower is on the top of tunnel, its speed is adjustable.

(7) Simple manual adjustment, and completed control.

(9) Cancel outer water collection tray, sealed. Can be used for high speed applications.

(10) Full body of tunnel is made of SS304 stainless steel

(11) Strong and easy 0perational handles on windows.

|

Models |

HF-1200M/G |

|

Length of tunnel |

1.2 0meters |

|

Main material |

SS304 |

|

Braided steam soft tubes |

316 |

|

Blower powder |

Ø12, 0.25KW |

|

Running pressure |

Max 0.6Mpa |

|

Weight |

150kg |

|

Steam consumption |

30kg/h |

|

Powder supply of blower |

110~240V |

|

Entrance /exit height |

Max 350mm |

|

Entrance /exit width |

110~210mm |

|

Outline size (L*W*H, m) |

1.5*W0.45*1.5 |

* All specification and tooling requirements are subject to Accraply evaluation of all label and product samples. Specifications shown reflect standard machine capabilities. Accraply can also meet other specification requirements. Please email or call for details.